Going the Distance: Managing Freight Costs and Delivery Delays in 2022

Supply Chain Disruption Series: Article 2

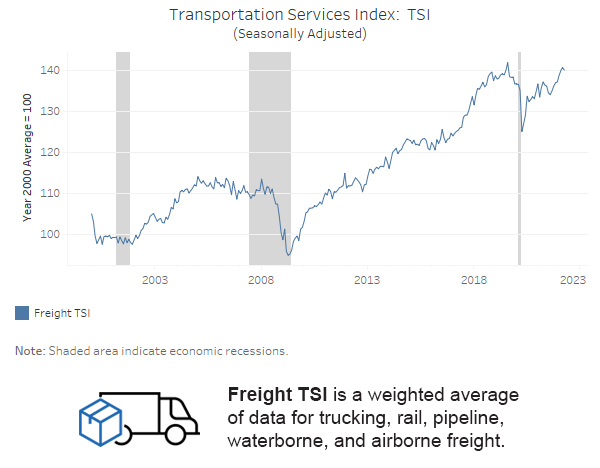

Due to the ongoing global supply chain crisis, companies face an uphill battle managing supply chain-related issues. On one front, companies are encountering frequent and extensive shipment and delivery delays. Information from Project44, which tracks global supply chains, reveals that shipment delays between China and major United States and European ports have quadrupled since late March 2022.1 On the other front, suppliers are enduring sky-high freight costs. The cost of shipping a container on a transoceanic trade route increased seven-fold in the 18 months that followed March 2020.2 Further, within the last couple of years, several large railroad companies significantly raised rates and demurrage fees.3 Although truck freight rates have begun to pull back from historic highs,4 the United States Department of Transportation’s Bureau of Transportation Statistics reported that the Freight Transportation Services Index (Freight TSI)5 for April of this year is still up 12% above the dip in for-hire freight shipments that occurred in April 2020.6

Bureau of Transportation Statistics, U.S. Department of Transportation, Freight Transportation Services Index, issued June 8, 2022

Reasons for Current Transportation Delays and Increased Freight Costs

There are three major issues affecting the state of transportation and related freight cost: the COVID-19 pandemic, the 2022 Russian invasion of Ukraine, and shipping issues in the supply chain.

The Effect of COVID-19 on Transportation in Supply Chains

COVID-19 spurred a number of changes that greatly impacted supply chains, leading to delivery delays and increased freight costs, including:

- Increased Demand for Consumer and Commercial Goods. Consumer demand for goods skyrocketed as circumstances required consumers to reduce spending on vacationing and eating out at restaurants, resulting in more disposable income for making purchases of goods.7 The appetite for products increased further as the labor force transitioned to work-from-home and spent more on new home offices and improving the home environment.8 Consumer spending on durable goods rose 30.8% from February 2020 through April 2021.9 On the commercial side, companies veered away from using just-in-time inventory management due to the delays and inability to get resources during government-imposed COVID-19 restrictions. Eyeing their depleted inventory levels, these companies began ordering more goods to have a bigger buffer stock.10 The result of this increased ordering of goods from both the consumer and the commercial sides overwhelmed an already fragile supply chain.

- Trucking Industry Challenges. The trucking industry has long been plagued by high turnover rates, an aging workforce, and drivers unsatisfied with the long hours away from home and uncomfortable job conditions.11 The trucking industry is highly cyclical in nature. For example, in 2019 (pre-pandemic), thousands of truck drivers lost their jobs, and the $800 billion trucking industry dipped into a recession.12 As the pandemic spread, the shortage of employees due to sickness and quarantines13 piled atop a recent wave of retirements and attrition,14 thereby exacerbating the supply chain transportation crisis in the United States. According to the American Trucking Association, in 2021, trucking companies suffered a shortage of more than 80,000 drivers.15

- Shipping Industry Issues. Between 2011 and 2018, three shipping alliances increased their share of the shipping container market from 29% to 80%. These alliances currently control 95% of trans-Pacific routes. Consolidations and bankruptcies in the shipping industry made it easier for shippers to increase prices dramatically.16 In addition, shipping container shortages prevented some companies who had product available from shipping it.

- Chinese Factory Closures and Re-Openings. China reacted to COVID-19 with strict lockdowns that shut down entire cities, including their factories. As various Chinese cities emerge from lockdown, such as China’s tech hub Shenzhen (which exited lockdown earlier this year), pent-up cargo has entered supply chain routes, exacerbating the transportation issues and leaving the question as to whether the transportation will be available to move the goods as quickly as needed.17

The 2022 Russia Invasion of Ukraine

The Russia invasion of Ukraine also increased the cost of shipping freight. Governments around the world levied embargos on Russian oil, resulting in increased costs for the remaining available fuel for purchase.18 Gas prices are not the only factor increasing overall shipping costs: the sinking of several ships in the Black Sea in connection with the Russia and Ukraine conflict has spurred insurers to hike premiums to between 1% and 5% of the value of the ship compared to pre-war levels of 0.25%.19

The fallout from the Russia/Ukraine conflict and related sanctions cannot be understated. For more information concerning the impact of the conflict on the supply chain, stay tuned for our upcoming article from David Simon and Mike Walsh, which will cover this issue in detail.

Miscellaneous Shipping Issues

There are a handful of other issues impacting the cost and timeliness of freight transportation:

- Labor Shortages. Widespread labor shortages, exacerbated further by China’s zero-tolerance COVID-19 policies, are affecting the cost of transportation for consumer goods.20

- Port Logjams. Port congestion continues due to perpetuating labor issues, growing container volumes, and quarantine measures in China. A future article in this Supply Chain Disruptions Series will explore how port logjams continue to impact transportation costs and delivery delays.

- Labor Negotiations. Unionized port workers are cognizant of the indispensable nature of the crucial role they play in global trade. Labor contracts for over 22,000 West Coast port workers (who handle approximately 42% of all US containerized trade with East Asia) are set to expire this summer.21 Failure to resolve the labor contracts will aggravate the current port logjam issues.

- Lack of Warehouse Space. Ship operators have diligently purchased new containers to address the lack of containers that grew out of the COVID-19 pandemic.22 In fact, ship operators and brokers estimate that they are moving eight million more containers than before the pandemic.23 This increase in containers led to a shortage in warehouse space to store the containers and inventory, further slowing the movement of goods along supply chains.24

For more information about port city logjams and related shipping issues, be on the lookout for our upcoming article from David Lucey, John Melko, and Leslie Smith.

Reducing Risk Related to Transportation Costs and Delays

As more fully discussed below, companies can use several approaches to reduce risk related to transportation delays and increased freight costs: (1) companies may try to obtain a more consistent supply by dual sourcing for their purchase of goods using geo-diverse suppliers; (2) companies may consider moving production locations to reduce the distance the product must travel; and (3) companies may evaluate their current insurance policies and commercial contracts to see if such arrangements can be adjusted to appropriately allocate delivery delay risk going forward.

Dual Sourcing

Beyond completely switching to domestic suppliers to obtain more consistent delivery times, companies may also consider dual sourcing (i.e., using one or more suppliers to source a material) to have a more stable supply of materials for their products. Ideally, the suppliers would be located in diverse geographies so that a weather issue or other similar event (whether shipping-related or otherwise) does not impact the supply of raw materials by all suppliers. Although companies must evaluate the cost increases associated with dual sourcing to determine whether it would be financially more beneficial than enduring the delivery delay and freight costs that occur amidst a global supply chain disruption, it is often worthwhile to identify and qualify additional suppliers in preparation for inevitable supply delays.

Onshoring and Nearshoring

Onshoring or reshoring refers to the practice of moving overseas production back to the domestic company’s location. Nearshoring refers to the practice of moving overseas production nearby the domestic company’s location, usually in a neighboring company on the same continent. Moving some or all production back to consumer markets or to a nearby region almost always results in reduced transportation costs, though those reductions must be balanced against other potential cost increases incurred in connection with moving production. Often companies find that the reliability that comes with onshoring or nearshoring outweighs any associated cost increase.

Samsung, for instance, announced last year that it will build $17 billion semiconductor factory outside of Austin, Texas, as a way to increase “readiness and stability.”25 Similarly, Micron Technology, which is based in Boise, Idaho, announced plans to invest $150 billion globally to develop its line of memory chips, with production to be established in the United States if tax credits can make up for the higher costs of domestic manufacturing.26

Whether onshoring or nearshoring would help allay the impact of supply chain issues depends on whether the benefits of onshoring or nearshoring outweigh the loss of cheap labor provided by an overseas production system.

For a pro/con analysis of reshoring and nearshoring, see Accelerating Trends: Assessing the Supply Chain in a Post-Pandemic World.

Insurance Coverage

Companies should evaluate their insurance programs to determine to what extent, if any, they have coverage for goods lost or delayed in transit. When the Ever Given, a quarter-mile-long ship, became lodged in the Suez Canal in March 2021, that blockage prevented $10 billion of cargo a day from moving through the canal.27 Those companies who adequately insured their cargo were able to submit claims to cover their extensive losses stemming from the week-long delay.

Some types of insurance products that could offer protection against similar supply chain delays include cargo insurance, contingent business interruption (CBI) insurance, and supply chain risk insurance. Cargo insurance generally protects shipments of goods from losses, damages, or theft sustained during transit. CBI insurance generally protects against lost profits and extra expenses incurred as the result of an interruption of business suffered by a customer or supplier. Supply chain insurance generally protects against financial losses arising from your supply chain and covers a broader swath of events than CBI insurance. Some negative events that supply chain insurance could cover include government-related disruptions, pandemics, labor issues, and financial problems.

Commercial Contract Review

Whenever there is a significant change in tide that affects business, companies should consider whether their contracts should be adjusted to adjust the allocation of risk or take advantage of the current business climate. Some points of analysis with respect to addressing delivery delays and freight costs include:

- Shipping Terms. Regardless of whether a company is on the buy side or on the sell side, it should evaluate whether the Incoterms provisions or other shipping terms in its contracts are up-to-date. Common updates to Incoterms provisions include ensuring the Incoterms referenced (a) are the most recent version (Incoterms 2020), and (b) reflect the business’ current practice for delivery. If the current business climate supports a shift, companies may evaluate whether the Incoterms provisions could be updated to further minimize risk of incurring unforeseen transportation costs. In an ideal world for buyers, buy-side Incoterms would be Delivery Duty Paid (DDP) at the buyer’s destination, meaning that the seller is required to pay all import duties, taxes, execute customs formalities, and pay for all transportation costs.28 In an ideal world for sellers, sell-side Incoterms would be Ex Works (EXW) at the seller’s dock, which places the least burden on the seller, only requiring that the seller make the goods available and suitably packaged at the specified point of delivery.29

- Shipment Costs. Every contract for the purchase and sale of goods should explicitly define the extent to which each party is responsible for packaging and shipping costs. Buy-side companies typically seek transportation costs that are either included in the price of the good or are otherwise fixed costs. Sell-side companies typically seek to pass on transportation costs to the buyer, or have transportation costs subject to index adjustments such that overall pricing will adjust as overall transportation cost increases.

- Delivery Delay. Companies should be thoughtful about how they expect delivery delays to be handled and should update their contracts to reflect their expectations. Some questions companies can contemplate to ascertain whether their contracts should be updated as to delivery delays include:

- Are delivery dates approximate (as is typically desired by the seller)? Or is time of the essence as to delivery (as is typically desired by the buyer)?

- Who will be responsible for arranging and paying for expedited freight in the event of a delivery delay?

- What other remedies should be available to the buyer in the event of a delivery delay? Are these remedies exclusive (as is typically desired by the seller) or cumulative (as is typically desired by the buyer)?

- Will liquidated damages be imposed in the event of a delivery delay (as is sometimes desired by the buyer)? Is the provision enforceable as a liquidated damage and not as a penalty?

- Would it be more beneficial to have liquidated damages or contract damages? Although a liquidated damages clause helps provide clarity to the parties on damages, it also acts as a cap on damages.

- How do limitation of liability provisions affect the recovery of damages in the event of a delivery delay?

- Force Majeure. Companies should review their force majeure provisions and ensure that the terms address transportation delays caused by continued supply disruptions. Some questions to consider when evaluating force majeure provisions are:

- Are transportation delays, inability to obtain goods or materials, and supply chain issues considered “force majeure events”?

- Is there catch-all phrasing that would cover transportation delays, inability to obtain goods or materials, and supply chain issues?

- In the event of a force majeure event, does the buyer have the right to suspend or terminate any purchase orders, and/or terminate the entire agreement under the force majeure clause? Is there a time period after the seller declares force majeure that the buyer must wait before suspension or termination?

Stay tuned for a deeper dive into force majeure clauses in upcoming articles.

The Future of Delivery Delays and High Freight Costs in the Supply Chain

It is uncertain when delivery delays and high freight costs will return to baseline. The consensus is clear, however, that disruptions to supply chain transportation and freight are far from over. Victor Meyer, COO of the risk intelligence provider Supply Wisdom, expects U.S. ports could begin experiencing disruptions soon as a result of Chinese port delays.30 Julie Gerdeman, CEO of Everstream Analytics, a provider of supply chain risk analytics, expects that once the Shanghai lockdown is lifted a surge of exports out of the Shanghai-Ningbo container gateway will further elongate the timeframe for supply chain disruptions.31 The CEO of Hamburg-based Hapag-Lloyd, Germany’s largest container carrier, expects global supply chains disruptions will persist at least until the second half of this year.32 Companies would be wise to act now to reduce the risk of financial loss in the event of persistent transportation delays and freight cost increases.

Subscribe to the Supply Chain Disruption Series

To help you navigate these uncharted territories in supply chain, we invite you to subscribe to Foley’s Supply Chain Disruption series by clicking here.

1 He, Laura, Shipping delays are back as China’s lockdowns ripple around the world, CNN Business (May 6, 2022).

2 Yan Carrière-Swallow, How Soaring Shipping Costs Raise Prices Around the World, International Monetary Fund (March 28, 2022).

3 Finn, Teaganne, Biggest railroad companies profiting from supply chain crisis, watchdog alleges, NBC News (March 7, 2022).

4 O’Neal, Lydia, Trucking Boom Is Hitting the Brakes as Freight Demand Slows, The Wall Street Journal (April 13, 2022).

5 The Freight TSI is a weighted average of data for trucking, rail, pipeline, waterborne, and airborne freight. What the Transportation Services Index, Dow Transportation Index, and Cass Freight Index Tell Us, U.S. Department of Transportation (August, 2019).

6 April 2022 Freight Transportation Services Index (TSI): First decline after 7-Consecutive-Month Growth, United States Department of Transportation (May 11, 2022).

7 Goodman, Peter, How the Supply Chain Broke, and Why It Won’t Be Fixed Anytime Soon, The New York Times (October 22, 2021).

9 Barua, Akrur, A spring in consumers’ steps: Americans prepare to get back to their spending ways, Deloitte (June 28, 2021).

11 FACT SHEET: The Biden-Harris Administration Trucking Action Plan to Strengthen America’s Trucking Workforce, the White House (December, 16, 2021).

12 Premack, Rachel, Thousands of truck drivers lost their jobs in the 2019 trucking ‘bloodbath.’ Here’s why the $800 billion industry dipped into a recession, Business Insider (December 30, 2021).

13 Swanson, Ana and Bradsher, Keith, Supply Chain Woes Could Worsen as China Imposes New Covid Lockdowns, the New York Times (January 16, 2022).

14 Ngo, Madeleine and Ana Swanson, The Biggest Kink in America’s Supply Chain: Not Enough Truckers, the New York Times (November 9, 2021).

15 Goodman, Peter, The Real Reason America Doesn’t Have Enough Truck Drivers, The New York Times (February 9, 2022).

16 Goodman, Peter, American Importers Accuse Shipping Giants of Profiteering, The New York Times (May 4, 2022).

17 Daniel, Will, ‘Companies are beginning to panic’: Experts say China’s lockdowns will make inflation and the supply chain nightmare even worse, Fortune (April 23, 2022); He, Laura, Shipping delays are back as China’s lockdowns ripple around the world, CNN Business (May 6, 2022).

18 What’s Next for Oil And Gas Prices As Sanctions on Russia Intensity, J.P .Morgan (March 10, 2022).

19 Marc Jones, Snarled-up ports point to worsening global supply chain woes – report, Reuters (May 3, 2022); Saul, Jonathon, Ship insurance claims to rise as Black Sea remains high risk area, Allianz says, Reuters (May 10, 2022).

20 Telford, Taylor, Yes, there’s a tampon shortage. Here’s why., The Washington Post (June 13, 2022).

21 Saraiva, Augusta and Josh Eidelson, What West Coast Ports’ Labor Negotiations Mean for Your Packages, Bloomberg (May 25, 2022).

22 Paris, Costas, Shipping Companies Added Capacity, but Now Containers Are Stuck in Port, The Wall Street Journal (May 30, 2022).

25 The Associated Press, Samsung says it will build $17B chip factory in Texas, NPR (November 24, 2021).

27 Motoko Rich et al., Clearing the Suez Canal Took Days. Figuring Out the Costs May Take Years, The New York Time (June 23, 2021); Ever Given: Cargo ship returns through Suez Canal it blocked, BBC News (August 20, 2021).

28 International Chamber of Commerce, Incoterms 2020 88 (2019).

30 Daniel, Will, ‘Companies are beginning to panic’: Experts say China’s lockdowns will make inflation and the supply chain nightmare even worse, Fortune (April 23, 2022).

31 McGregor, Grady, A semiconductor CEO explains how Shanghai’s 7-week lockdown is crippling his supply chain and fueling inflation, Fortune (May 14, 2022).

32 Murray, Brendan. Global Shipping Trims the Sails Heading Into Economic Slowdown, Bloomberg (May 12, 2022).